Ultraviolet (UV) disinfection is an application widely used in clinical, hospital, pharmaceutical, food industry and water disinfection. The use of UV rays with a wavelength between 200 to 300 nm causes damages in the exposed DNA and RNA chains of the cells of microorganisms, including viruses (Setlow, 1967). These changes cause such damage that the cells are unable to reproduce. According to the International Ultraviolet Organisation (IUVA), Coronaviruses are generally believed to be very susceptible to UV-C radiation at around 254 nm. Controlled studies and predictive modelling show inactivation greater than 4 log (99.9999%) is achieved with radiation doses below 22 mJ / cm2. This year, studies carried out by the National Emerging Infectious Diseases Laboratories (NEIDL) at Boston University verified the elimination of SARS-CoV-2 with a dose of 5mJ/cm2 UV rays for 6 seconds, reaching an efficacy of 99%. Based on this data, the reduction of the microbiological load by 99.9999% has been calculated to occur in 25 seconds at a wavelength within the range of 200 to 300 nm.

CLICK HERE to contact Customer Service and request the full Aurora brochure

There is a wide range of applications where this clean and environmentally friendly technology can be used in the food and beverage industry as part of an air quality improvement plan including:

- High traffic areas

- Corridors and changing rooms

- Laboratories

- Within the production environment.

Aurora UV-C Technology is Available both for Air and Surface Disinfection

Air disinfection can be a continuous process using forced air tunnels that incorporate enclosed UV lamps that are suspended within the area or installing UV-C lamps in front of existing air handling units. Disinfection of surfaces including conveyor belts can be carried out between production shifts when people are not present. This can be achieved by installing UV-C lamps above the surfaces that require disinfection or underneath conveyor belts.

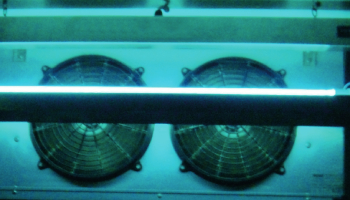

Forced Air Tunnel

Airflow rates: from 40 to 450 m3/h.

Ceiling Bowels

Radiation (1m): from 1400 to 5600 mW/m2.

Conveyor Belt Unit

- Adjustable in size to fit different conveyor dimensions

- Removable tray with lamps for easy dismantling during cleaning operations

- Above or below conveyor installation (requires a “free from food” area of the conveyor to ensure effective irradiation of the belt, but not directly on to food)

Benefits of UV Disinfection

Aurora air disinfection provides better air quality in the production or storage environment, which has been proven to increase the shelf life of stored items, reduce odours and reduce bacteria proliferation. Additional benefits include:

- Safe to use for your product, process and operators

- No waste

- No damage to the environment

- Free of chemicals

- Low maintenance

- Shatterproof lamps

- Lamp life counter

To achieve the required efficacy, surfaces must be clean and free from dirt before UV disinfection is carried out. Surfaces should be cleaned using an effective and suitable detergent.

We recommend that surface disinfection with exposed UV-C lamps is completed with the absence of anyone in the room. Full PPE including UV visor should be worn if an operative is present.